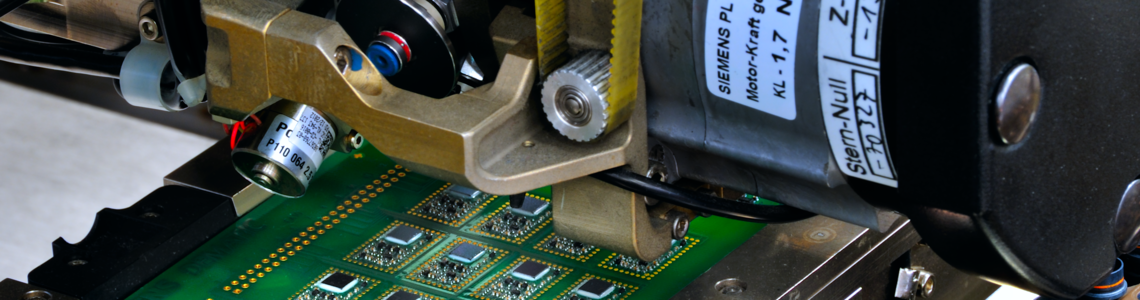

PCB Assembly

Our printed circuit board (PCB) assembly materials offer excellent performance and high productivity. Moreover, these PCB adhesives facilitate equipment savings and reduce technology investment, adding to your customers’ bottom line. Being able to match materials for PCB assemblies provides consistency in manufacturing processes and product performance.

We offer a broad range of PCB adhesive products, from multiple chemistries with multiple PCB assembly applications, including urethane, acrylic, epoxy, and silicone chemistries—all of which are used in conformal coatings, adhesives (die attach, surface mount, thermal conductivity) and potting/encapsulants. In addition, device reliability is a critical measure of product performance in the electronics industry, whether the application is for consumer or industrial assembly applications. H.B. Fuller’s range of high-performance underfill and edgebond materials offer reliable structural reinforcement of sensitive device components as well as balanced re-workability, depending on specific customer requirements.

H.B. Fuller underfills typically offer:

- High reliability (drop, shock, autoclave and temperature cycle)

- Fast flow and easy processing

- Rework versus reliability balance

- Excellent flux compatibility

- Detailed product performance characteristics

- High reliability edgebonds (replacing full underfill)

Feature applications include:

- Capillary Underfill for BGA/WLCSP/FlipChip

- Edge Bonding

- Solder joint/passive chip encapsulant

- COB (Chip on board) Encapsulant

- Chip reinforcement

- Surface mount adhesive

- Conformal coating and potting