View Related Pages

Automotive Electronics Adhesives

Automotive Electronics Adhesives

Automotive electronic adhesives offer exceptional performance in bonding crucial, dissimilar electronic components. H.B. Fuller’s SV Series redefines industry standards in applications such as cameras, ADAS, displays, and mirrors.

View More

Bus

Bus

H.B. Fuller offers a full line of adhesives for the bus and railway transportation industries, including structure bonding and vibration/noise reduction. Our products offer greater travel comfort while boosting passenger safety.

View More

Commercial Vehicles

Commercial Vehicles

At H.B. Fuller, we provide a line of versatile adhesives and sealants designed specifically for the commercial vehicle industry, including emergency and specialty vehicles, bus and rail transportation, and trucks and trailers.

View More

Heavy Machinery and Agricultural

Heavy Machinery and Agricultural

H.B. Fuller's heavy machinery adhesives are globally present in agriculture, construction, and mining equipment. Partner with us for high-performance technologies that ensure the safety and durability of your heavy machinery.

Learn More

MRO

MRO

H.B. Fuller offers adhesive products for maintenance, repair, and operating supplies in various industries, including power plants, manufacturing, mining, metallurgy, HVAC and vehicle repair, facility maintenance, and marine.

Read More

Rail

Rail

When it comes to railcar interiors, adhesives and sealants enhance passenger experience. By improving acoustics, providing stability, and enabling lighter materials, H.B. Fuller solutions create a comfortable and pleasant commute.

Read More

Truck and Trailer

Truck and Trailer

Dedicated to commercial-scale production of bonding and sealing products, we are passionate about helping you better produce higher quality, lower weight commercial vehicles—with greater efficiency and at lower production costs.

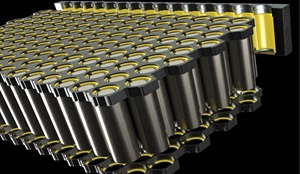

The EV Protect product line includes lightweight and standard density flame retardant encapsulants. They are liquid applied, two-component, polyurethane technologies that provide fire protection to EV battery modules. In the event of thermal runaway, EV Protect is specifically designed to isolate the event, insulate any adjacent cells from heat and fire, and reduce the chances of thermal propagation.

The EV Protect product line includes lightweight and standard density flame retardant encapsulants. They are liquid applied, two-component, polyurethane technologies that provide fire protection to EV battery modules. In the event of thermal runaway, EV Protect is specifically designed to isolate the event, insulate any adjacent cells from heat and fire, and reduce the chances of thermal propagation.

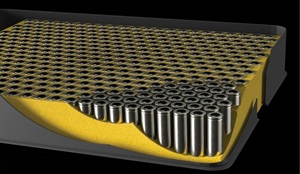

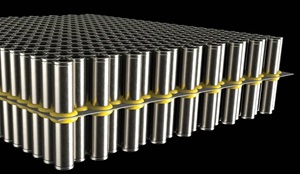

With the critical nature of thermal management strategy for battery systems, the EV Therm product line was created to optimize heat transfer between battery cells and cooling systems. Our EV Therm product offerings include thermally conductive coatings, thermal interface materials (TIMs), and thermally conductive adhesives. Each product is designed to minimize the heat retention in the battery module and improve battery efficiency.

With the critical nature of thermal management strategy for battery systems, the EV Therm product line was created to optimize heat transfer between battery cells and cooling systems. Our EV Therm product offerings include thermally conductive coatings, thermal interface materials (TIMs), and thermally conductive adhesives. Each product is designed to minimize the heat retention in the battery module and improve battery efficiency.